Readings Newsletter

Become a Readings Member to make your shopping experience even easier.

Sign in or sign up for free!

You’re not far away from qualifying for FREE standard shipping within Australia

You’ve qualified for FREE standard shipping within Australia

The cart is loading…

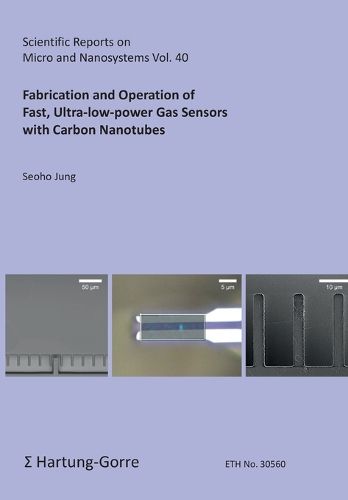

The exceptional properties of carbon nanotubes (CNTs), including their high mechanical strength, electron mobility, and thermal conductivity, make them promising candidates for various applications. One possible application is the sensing of nitrogen dioxide (NO2), a toxic pollutant with significant implications for air quality monitoring, pollution control, and medical applications. Existing sensor technologies often fail to meet the stringent requirements for power consumption, shelf life, readout speed, and limit of detection (LOD) necessary for mobile applications. CNT-based gas sensors offer substantial potential to address these limitations, yet several challenges must be overcome to utilize their full potential. One major technological hurdle is the high-volume fabrication of CNT devices, in particular that of suspended CNT devices, which demonstrate several advantages as sensors. This thesis presents an approach to address this challenge, focusing on the scalable batch growth of suspended CNTs and their automated assembly into functional devices. Through systematic multi-parameter optimization and the development of large-scale growth substrates, the optimal growth conditions for CNTs were identified, leading to a significant increase in the number of individual CNTs available for device integration. An automated nanoassembly machine was employed to transfer pre-selected CNTs from growth substrates to device substrates. The process flow designed around automated robotic assembly demonstrates a production rate - mechanical transfer rate for carbon nanotubes - of approximately 46 CNTs per hour, with a 70 % yield of electrically active devices. The assembled devices were characterizedelectrically to understand the performance of devices fabricated by this method.

$9.00 standard shipping within Australia

FREE standard shipping within Australia for orders over $100.00

Express & International shipping calculated at checkout

The exceptional properties of carbon nanotubes (CNTs), including their high mechanical strength, electron mobility, and thermal conductivity, make them promising candidates for various applications. One possible application is the sensing of nitrogen dioxide (NO2), a toxic pollutant with significant implications for air quality monitoring, pollution control, and medical applications. Existing sensor technologies often fail to meet the stringent requirements for power consumption, shelf life, readout speed, and limit of detection (LOD) necessary for mobile applications. CNT-based gas sensors offer substantial potential to address these limitations, yet several challenges must be overcome to utilize their full potential. One major technological hurdle is the high-volume fabrication of CNT devices, in particular that of suspended CNT devices, which demonstrate several advantages as sensors. This thesis presents an approach to address this challenge, focusing on the scalable batch growth of suspended CNTs and their automated assembly into functional devices. Through systematic multi-parameter optimization and the development of large-scale growth substrates, the optimal growth conditions for CNTs were identified, leading to a significant increase in the number of individual CNTs available for device integration. An automated nanoassembly machine was employed to transfer pre-selected CNTs from growth substrates to device substrates. The process flow designed around automated robotic assembly demonstrates a production rate - mechanical transfer rate for carbon nanotubes - of approximately 46 CNTs per hour, with a 70 % yield of electrically active devices. The assembled devices were characterizedelectrically to understand the performance of devices fabricated by this method.