Readings Newsletter

Become a Readings Member to make your shopping experience even easier.

Sign in or sign up for free!

You’re not far away from qualifying for FREE standard shipping within Australia

You’ve qualified for FREE standard shipping within Australia

The cart is loading…

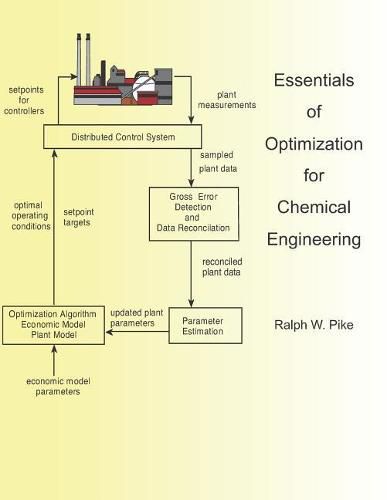

There are multiple levels of optimization that must be considered. One level is the optimal scheduling problem of corporate headquarters to distribute raw materials among the company’s plants to maximize profits in producing, transporting, and marketing products to consumers worldwide. Also included is the optimal scheduling problem of the individual plant to set operating conditions to produce required products from allocated raw materials for a maximum net profit or minimum cost of operations. The best schedule is determined for steady-state daily or weekly average flow rates for the plant. Finally, there is on-line optimization of process operations to determine the set-points for the distributed control system of the individual process units in the plant which give the best operating conditions while producing the specified quality and quantity of products. Also, on-line optimization keeps track of such things as catalyst deactivation and scaling in heat exchangers by parameter adjustments in the process models of the units from sampling plant data. This book is at the interface of mathematics and industrial applications of optimization. The topics were selected for their breadth of application to the optimization of engineering systems, especially continuous ones. Also, the mathematics of optimization is presented to provide the foundation for these methods that have proven successful in industrial applications.

$9.00 standard shipping within Australia

FREE standard shipping within Australia for orders over $100.00

Express & International shipping calculated at checkout

There are multiple levels of optimization that must be considered. One level is the optimal scheduling problem of corporate headquarters to distribute raw materials among the company’s plants to maximize profits in producing, transporting, and marketing products to consumers worldwide. Also included is the optimal scheduling problem of the individual plant to set operating conditions to produce required products from allocated raw materials for a maximum net profit or minimum cost of operations. The best schedule is determined for steady-state daily or weekly average flow rates for the plant. Finally, there is on-line optimization of process operations to determine the set-points for the distributed control system of the individual process units in the plant which give the best operating conditions while producing the specified quality and quantity of products. Also, on-line optimization keeps track of such things as catalyst deactivation and scaling in heat exchangers by parameter adjustments in the process models of the units from sampling plant data. This book is at the interface of mathematics and industrial applications of optimization. The topics were selected for their breadth of application to the optimization of engineering systems, especially continuous ones. Also, the mathematics of optimization is presented to provide the foundation for these methods that have proven successful in industrial applications.