Readings Newsletter

Become a Readings Member to make your shopping experience even easier.

Sign in or sign up for free!

You’re not far away from qualifying for FREE standard shipping within Australia

You’ve qualified for FREE standard shipping within Australia

The cart is loading…

This title is printed to order. This book may have been self-published. If so, we cannot guarantee the quality of the content. In the main most books will have gone through the editing process however some may not. We therefore suggest that you be aware of this before ordering this book. If in doubt check either the author or publisher’s details as we are unable to accept any returns unless they are faulty. Please contact us if you have any questions.

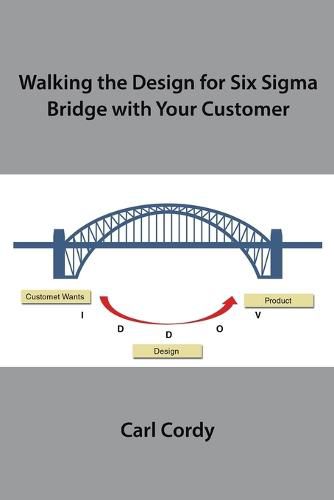

Besides providing a technical overview of design for Six Sigma, this is a text that goes the extra step beyond in presenting real-life examples of structured tool use to satisfy the needs of the customer. The discussion covers the background behind the tools used and real-life examples of their use. The general theme of this text is to know what the customer wants out of a product or service and to keep these in mind throughout the project life cycle through implementation.

Topics are arranged in the design cycle that Taguchi devised: identify, define, develop, optimize, and verify. Throughout the book, Carl Cordy presents the technical discussion and example applications with a reminder as to why we are using them: to satisfy customer wants and desires for a product or service. Also, as continuous improvement, design for Six Sigma is part of a firm’s strategy for maintaining the competitive edge and ensuring it is the supplier of choice for its goods and services with its current and potential customers.

Specific tools covered–including survey design, Kano analysis, quality functional deployment, and SWOT–are examples of soft or subjective analysis tools. Risk analysis includes DFMEA, fault tree, and variation effect analysis. The hard or quantification tools include regression analysis, designed experiments, response surface, and transfer function generation. At the end of topic discussion, a sample real-life project illustrates tool use from start to end.

The last set of tools and principles includes the initial setting of tolerances in a linked pattern from system performance to component tolerances. A new concept of determining the value of a design includes placing a financial number on its function. A discussion of ensuring the design makes both mathematical and physical sense wrap up the tools discussion.

Finally, the conclusion briefly sums up the design cycle phases and tools used to complete the actions from identifying customer needs to verification and validation of the physical system. The last statement is an emphasis on ensuring that we continue to understand what the customer wants and needs out of the system we provide.

$9.00 standard shipping within Australia

FREE standard shipping within Australia for orders over $100.00

Express & International shipping calculated at checkout

This title is printed to order. This book may have been self-published. If so, we cannot guarantee the quality of the content. In the main most books will have gone through the editing process however some may not. We therefore suggest that you be aware of this before ordering this book. If in doubt check either the author or publisher’s details as we are unable to accept any returns unless they are faulty. Please contact us if you have any questions.

Besides providing a technical overview of design for Six Sigma, this is a text that goes the extra step beyond in presenting real-life examples of structured tool use to satisfy the needs of the customer. The discussion covers the background behind the tools used and real-life examples of their use. The general theme of this text is to know what the customer wants out of a product or service and to keep these in mind throughout the project life cycle through implementation.

Topics are arranged in the design cycle that Taguchi devised: identify, define, develop, optimize, and verify. Throughout the book, Carl Cordy presents the technical discussion and example applications with a reminder as to why we are using them: to satisfy customer wants and desires for a product or service. Also, as continuous improvement, design for Six Sigma is part of a firm’s strategy for maintaining the competitive edge and ensuring it is the supplier of choice for its goods and services with its current and potential customers.

Specific tools covered–including survey design, Kano analysis, quality functional deployment, and SWOT–are examples of soft or subjective analysis tools. Risk analysis includes DFMEA, fault tree, and variation effect analysis. The hard or quantification tools include regression analysis, designed experiments, response surface, and transfer function generation. At the end of topic discussion, a sample real-life project illustrates tool use from start to end.

The last set of tools and principles includes the initial setting of tolerances in a linked pattern from system performance to component tolerances. A new concept of determining the value of a design includes placing a financial number on its function. A discussion of ensuring the design makes both mathematical and physical sense wrap up the tools discussion.

Finally, the conclusion briefly sums up the design cycle phases and tools used to complete the actions from identifying customer needs to verification and validation of the physical system. The last statement is an emphasis on ensuring that we continue to understand what the customer wants and needs out of the system we provide.